Introduction To : Okamoto Igm15nc Toy Shaft

Toy manufacturing has evolved significantly over the years, and one crucial aspect of the production process is toy shaft grinding. The Okamoto IGM15NC toy shaft is a groundbreaking machine that has transformed precision grinding, making it more efficient and accurate than ever before. But what makes this machine so special? And how does it impact the future of toy production? Let’s dive in and explore.

Understanding Toy Shaft Grinding

Toy shaft grinding is the process of refining small shafts used in toy mechanisms, ensuring smooth rotation and durability. Without precision grinding, toys would lack the finesse needed for seamless performance.

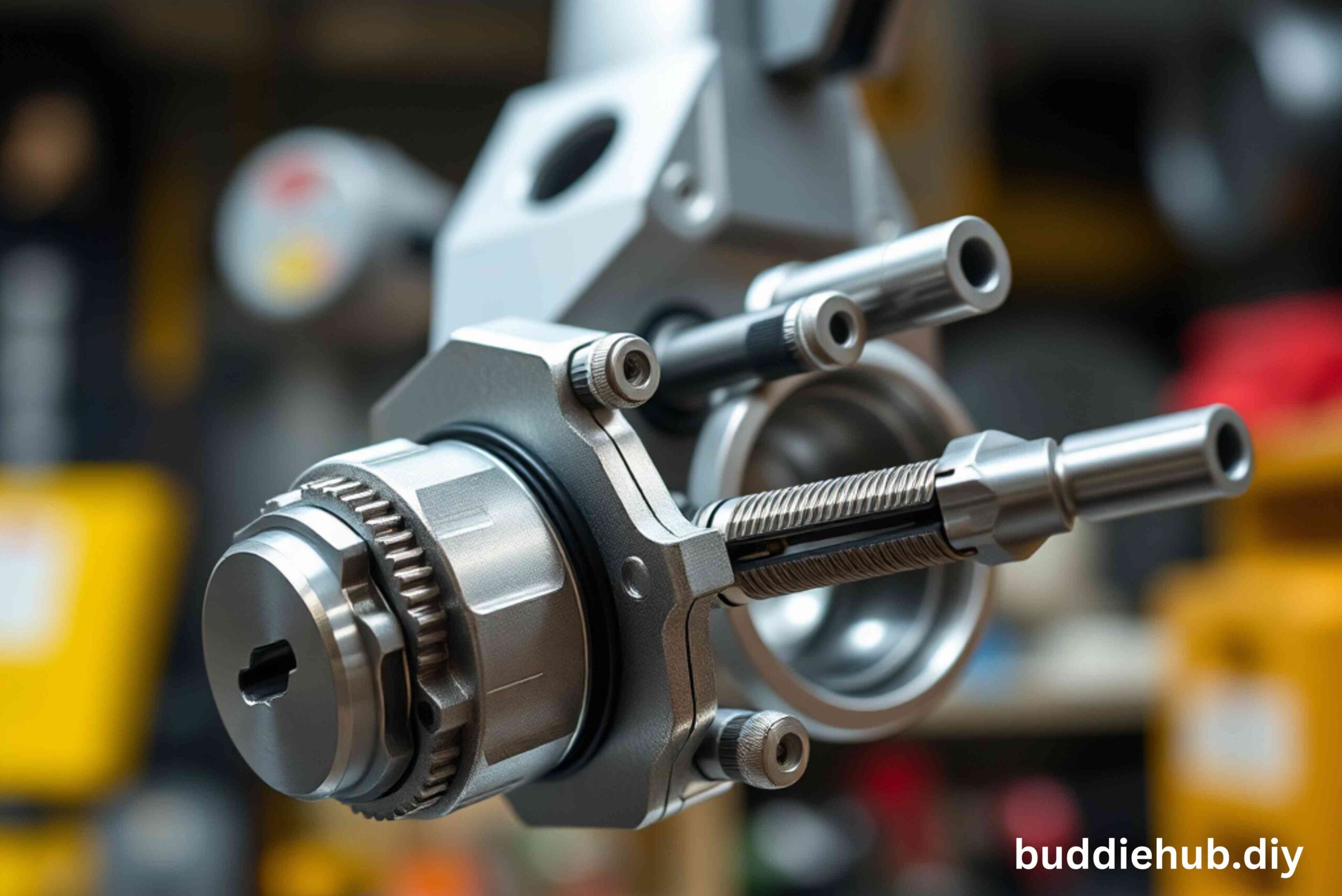

What is the Okamoto IGM15NC Toy Shaft?

The Okamoto IGM15NC is an advanced internal grinding machine designed specifically for small shafts. It combines precision engineering with cutting-edge automation to deliver unparalleled accuracy.

Key Features of the Okamoto IGM15NC

- CNC Control: Ensures automated precision.

- High-Speed Grinding: Reduces processing time.

- Compact Design: Perfect for small components.

- User-Friendly Interface: Easy to operate.

- Versatile Applications: Works on multiple materials.

How Does the Okamoto IGM15NC Work?

The machine operates using computer numerical control (CNC), which dictates grinding movements with extreme precision. The grinding wheel shapes and polishes the toy shaft, ensuring perfect symmetry and smooth surfaces.

Advantages Over Traditional Grinding Machines

- Higher Accuracy: CNC control eliminates human error.

- Faster Processing: Automated functions reduce grinding time.

- Consistent Quality: Produces uniform shafts for toys.

Applications of Toy Shaft Grinding

The Okamoto IGM15NC is widely used in toy manufacturing, robotics, and small-scale mechanical devices. Precision-ground shafts are crucial for electric toy cars, action figures with moving parts, and more.

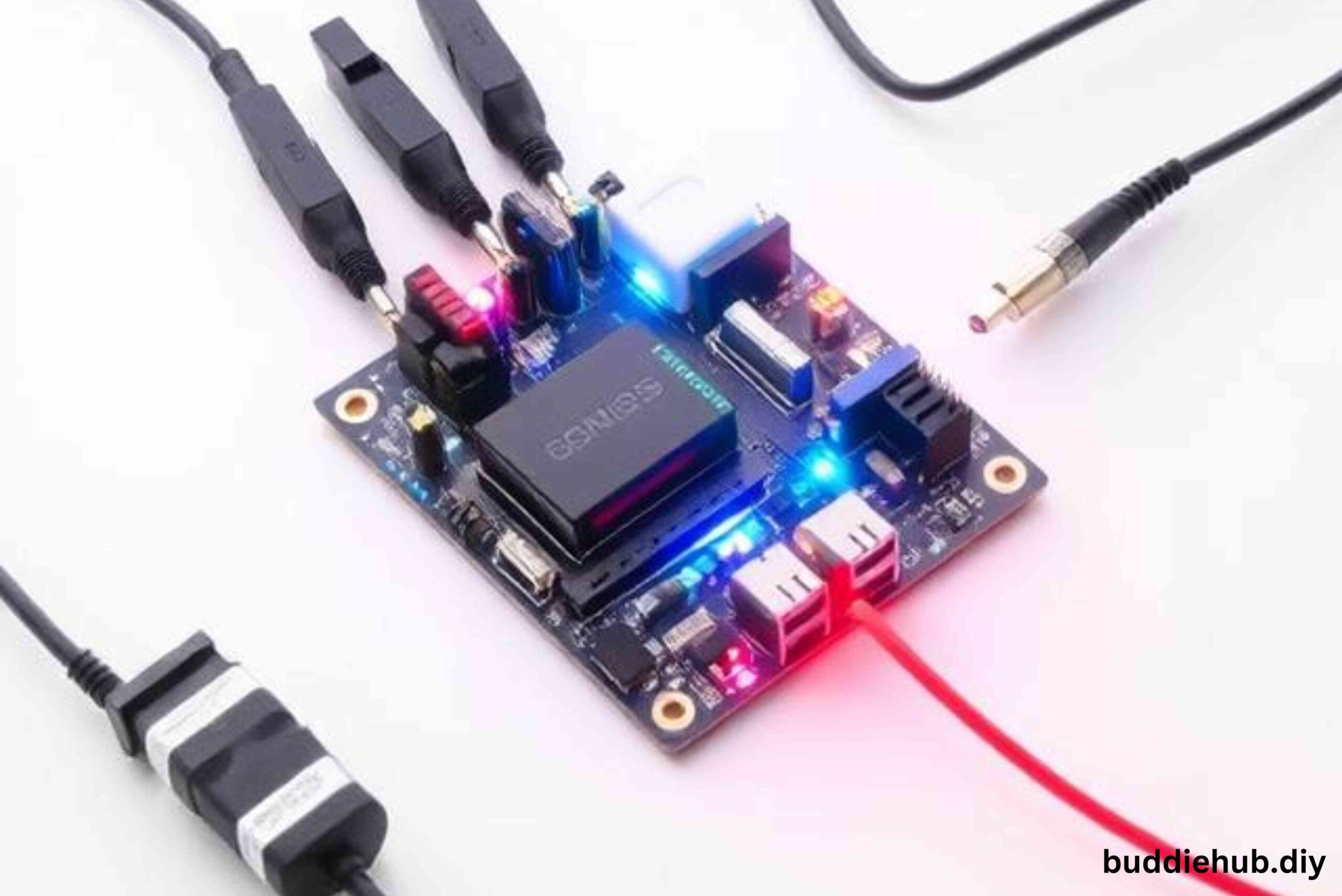

The Role of Automation in Shaft Grinding

Automation reduces labour costs and increases production efficiency. The Okamoto IGM15NC’s CNC system ensures each shaft is ground to perfection without manual intervention.

Precision and Efficiency: A Game Changer

The demand for high-precision toy parts is growing, and the Okamoto IGM15NC is setting new standards with its micron-level accuracy and repeatability.

Future Innovations in Toy Shaft Grinding

- AI Integration: Smarter, self-adjusting grinding processes.

- Eco-Friendly Coolants: Reduced environmental impact.

- Faster Production Rates: Enhanced automation.

How the Okamoto IGM15NC Stands Out

Compared to other grinding machines, the Okamoto IGM15NC offers a unique blend of speed, accuracy, and automation, making it the preferred choice for manufacturers worldwide.

Common Issues and Troubleshooting

- Grinding Wheel Wear: Regularly replace worn wheels.

- Misalignment Issues: Calibrate the CNC system properly.

- Overheating: Ensure adequate cooling during operation.

Maintenance and Longevity

Regular maintenance, such as cleaning, lubrication, and part replacements, can extend the machine’s lifespan and maintain optimal performance.

Environmental Impact and Sustainability

Using energy-efficient motors and recyclable materials in grinding processes can make toy shaft production more sustainable and environmentally friendly.

Is the Okamoto IGM15NC Worth the Investment?

For manufacturers aiming for precision and efficiency, the Okamoto IGM15NC is a cost-effective solution that boosts productivity and ensures consistent quality.

Final Thoughts on the Future of Toy Shaft Grinding

The Okamoto IGM15NC is shaping the future of toy manufacturing by providing unmatched precision and automation. As technology advances, we can expect even more groundbreaking innovations in the industry.

FAQs

- What makes the Okamoto IGM15NC different from other grinding machines?

Its CNC automation, high-speed operation, and precision engineering set it apart from traditional grinders.

- Can the Okamoto IGM15NC be used for materials other than metal?

Yes, it can grind various materials, including ceramics, plastics, and composites.

- How long does a typical grinding process take?

The time varies, but thanks to its high-speed capabilities, it is significantly faster than manual grinding methods.

- Is the Okamoto IGM15NC suitable for small-scale manufacturers?

Absolutely! Its compact design and automated features make it ideal for both large and small manufacturers.

- How can I maintain the Okamoto IGM15NC for long-term use?Regular cleaning, lubrication, and timely part replacements will ensure its longevity and optimal performance.

Conclusion :

The Okamoto IGM15NC toy shaft is a revolutionary machine in the toy industry, offering efficiency, precision, and reliability. As technology advances, the future of toy shaft grinding looks brighter than ever!